Forwa has been engaged in

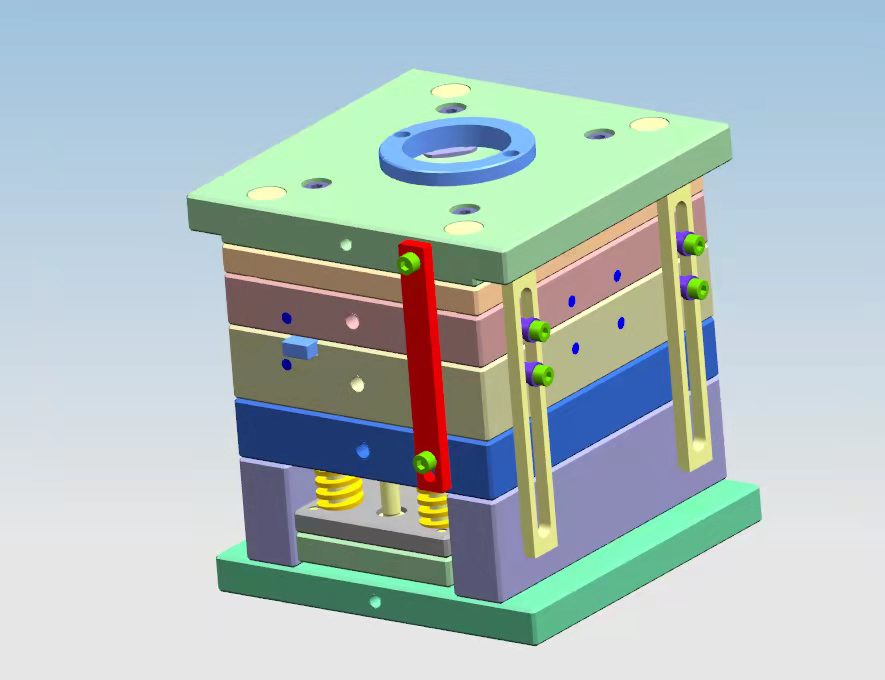

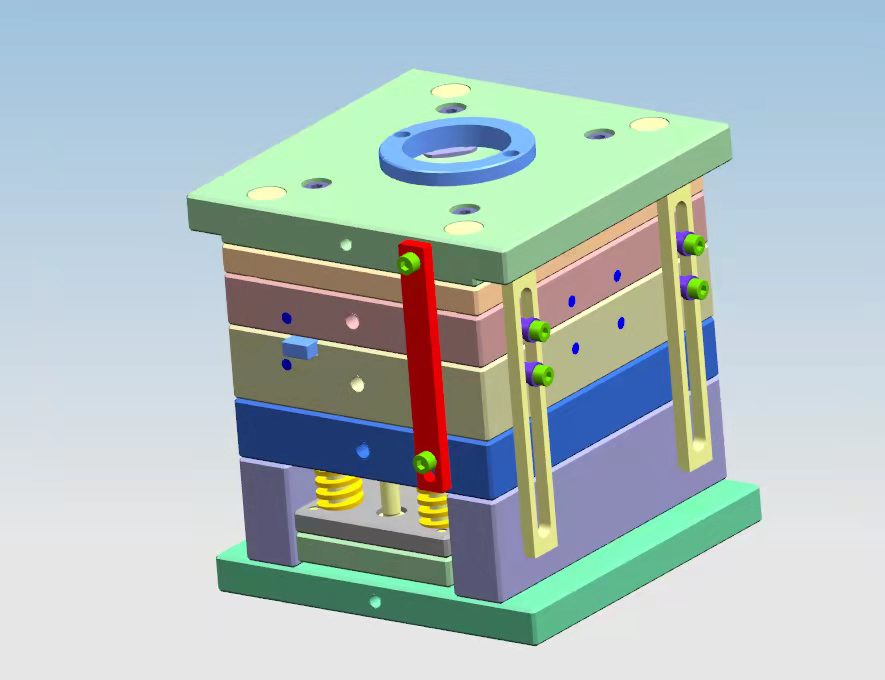

plastic mold production for 20+ years. with 10 years of experience in plastic mold engineers 20, with 5 years of experience in plastic mold production technicians 30. The structure of the plastic mold can be divided into 2- plate mold and 3-plate mold. What is the difference between the structure of the 2-plate mold and the 3-plate mold of the plastic mold?

1.2-plate plastic mould less than 3-plate

plastic mould one plate, that is stripper plate

2. 2-plate plastic mold is only A B plate parting, that is, there is only one parting surface. And the 3-plate plastic mold has the stripping plate and the A plate, the stripping plate and the clamp plate between the parting surface.

3. For the 2-plate die of the plastic mold, the sprue is directly connected to the parting surface of plate A, while the sprue of the 3-plate die is connected to the bottom surface of plate A.

4. The components of the 3-plate die of the plastic mold are more than those of the 2-plate die. The main components are the following grasping pins, external pull rods or plastic openers, internal pull rods, etc.

5.The runner weight of 2-plate plastic mold is lighter than the one of 3-plate plastic mould

6.The runner of 3-plate plastic mold can fall off automatically,which can reduce the labor cost. But the runner of 2-plate plastic mold may be manually cut.